In the modern world of biotechnology, pharmaceuticals, and industrial microbiology, Bioreactor play a pivotal role in producing a wide range of products, from vaccines and enzymes to biofuels and cultured cells. At Fermenter Technologies, we specialize in designing and supplying advanced bio reactors and bioreactors that serve research, pilot, and large-scale industrial needs. We offer solutions that combine efficiency, precision, and scalability, making bioprocessing smoother and more reliable.

A bioreactor is a specially designed vessel that provides a controlled environment for the growth of microorganisms, cells, or biologically active substances. The primary goal of a bioreactor is to optimize conditions such as temperature, pH, oxygen supply, nutrient concentration, and agitation, so that biological reactions occur efficiently and consistently. This can range from microbial cultures used in enzyme production to mammalian cells used for therapeutic protein production.

Types of Bioreactor

Bioreactors come in various designs and configurations depending on the type of biological process and the scale of operation. Some commonly used types include:

- Stirred Tank Bioreactor: The most widely used type, suitable for bacterial, yeast, and mammalian cell cultures. The agitator provides uniform mixing and oxygen transfer.

- Airlift Bioreactor: Uses gas to circulate the culture medium, ideal for shear-sensitive cells.

- Packed Bed Bioreactor: Contains immobilized cells or enzymes on a support matrix, used in continuous production systems.

- Photo-Bioreactor: Designed for photosynthetic organisms such as algae, with light provided to drive growth.

- Disposable/SINGLE-USE Bioreactor: Made from pre-sterilized bags, these bio reactors are gaining popularity for their convenience and reduced contamination risks.

Also Read: Scale Up of Fermentation Process

How Does a Bioreactor Work?

A bioreactor works by maintaining an environment where biological reactions can occur efficiently. At its core, the process involves three main steps:

- Preparation and Inoculation: First, the bioreactor is cleaned, sterilized, and filled with a nutrient-rich medium. Then, microorganisms, animal cells, or plant cells are introduced into the system.

- Growth and Production: Once inside the bioreactor, the organisms begin to grow and multiply. Sensors and control systems regulate temperature, pH, oxygen supply, and agitation. For instance, oxygen is supplied through spargers, and mixing ensures even distribution of nutrients. This controlled environment allows the cells to produce the desired product, such as insulin, antibiotics, or ethanol.

- Harvesting and Downstream Processing: After sufficient growth and production, the product is separated from the cells and the medium. This may involve filtration, centrifugation, or chemical extraction. The harvested product is then purified for industrial or medical use.

It allows industries to mass-produce biological products that would be impossible to achieve at the same scale naturally.

Applications of Bioreactor

The applications of bioreactors span multiple industries, making them indispensable in modern biotechnology:

- Pharmaceutical Industry: For producing vaccines, therapeutic proteins, and monoclonal antibodies.

- Food and Beverage Industry: Used in fermentation processes to produce beer, wine, yogurt, and other products.

- Biofuel Production: Cultivation of microorganisms for ethanol, biodiesel, and other renewable energy sources.

- Environmental Applications: Wastewater treatment and bioremediation processes rely on bioreactors to degrade pollutants.

- Research and Development: Pilot-scale bioreactors enable scientists to study cellular processes, optimize growth conditions, and scale up production efficiently.

By using advanced bioreactors, industries can enhance productivity, maintain product consistency, and reduce production costs.

Why Bioreactors Are Important

A bioreactor is an essential for industrial and research applications. Some of the key benefits include:

- Controlled Environment: Maintains optimal conditions for growth and production.

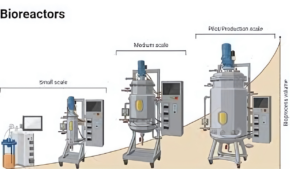

- Scalability: Processes can be scaled from laboratory research to industrial production without compromising quality.

- Consistency: Reduces variability in product quality by controlling parameters precisely.

- Automation: Modern bioreactors allow for automated monitoring and control, minimizing human error.

- Enhanced Yield: Proper design and operation increase productivity and reduce waste.

Fermenter Technologies stands out as a leading company that continues to offer cutting-edge bioreactor systems tailored to industrial as well as research needs. Their solutions are designed to be user-friendly, durable, and efficient, making them a trusted name in the biotechnology sector.

Companies like Fermenter Technologies play a crucial role by continuing to innovate bioreactor solutions that drive progress in multiple industries. As biotechnology keeps advancing, bioreactors will remain at the center of innovation, shaping a better, more sustainable future.