Biotechnology and industrial microbiology have evolved significantly, and at the heart of this revolution lies the bioreactor, a smooth system designed to create an ideal environment for the growth of microorganisms, animal cells, or plant cells to produce valuable products. At Fermenter Technologies, we provide cutting-edge bioreactor solutions to meet the growing demand for efficient and sustainable bioprocessing.

Bioreactor Design:

A bioreactor is essentially a closed vessel that is careful to control environmental conditions like temperature, pH, oxygen transfer, agitation, and nutrient supply. The design of a bioreactor depends on the type of biological process—whether it is aerobic, anaerobic, or continuous fermentation.

Typical bioreactor designs include:

- Cylindrical Vessels: Most bioreactors are vertical cylinders with a height-to-diameter ratio of about 2:1, ensuring good mixing and aeration.

- Agitation System: Blade or stirrers keep the contents well-mixed for uniform conditions.

- Aeration System: Sprinkle introduces sterile air or gases into the culture medium.

- Sensors and Control Units: These measure temperature, pH, dissolved oxygen, and foam levels to maintain optimal growth conditions.

The design aims to mimic natural conditions while maximizing product yield under sterile and controlled circumstances.

Bioreactor Principle:

The principle of a bioreactor is based on providing a controlled environment where biological reactions can take place efficiently. It involves:

- Supplying Nutrients: The medium is enriched with essential nutrients required by the cells.

- Maintaining Optimal Conditions: Temperature, pH, and oxygen are continuously monitored and adjusted.

- Removing Waste Products: By-products are removed to prevent reserve of cell growth.

- Ensuring Sterility: Contamination is avoided to protect the culture and maintain product purity.

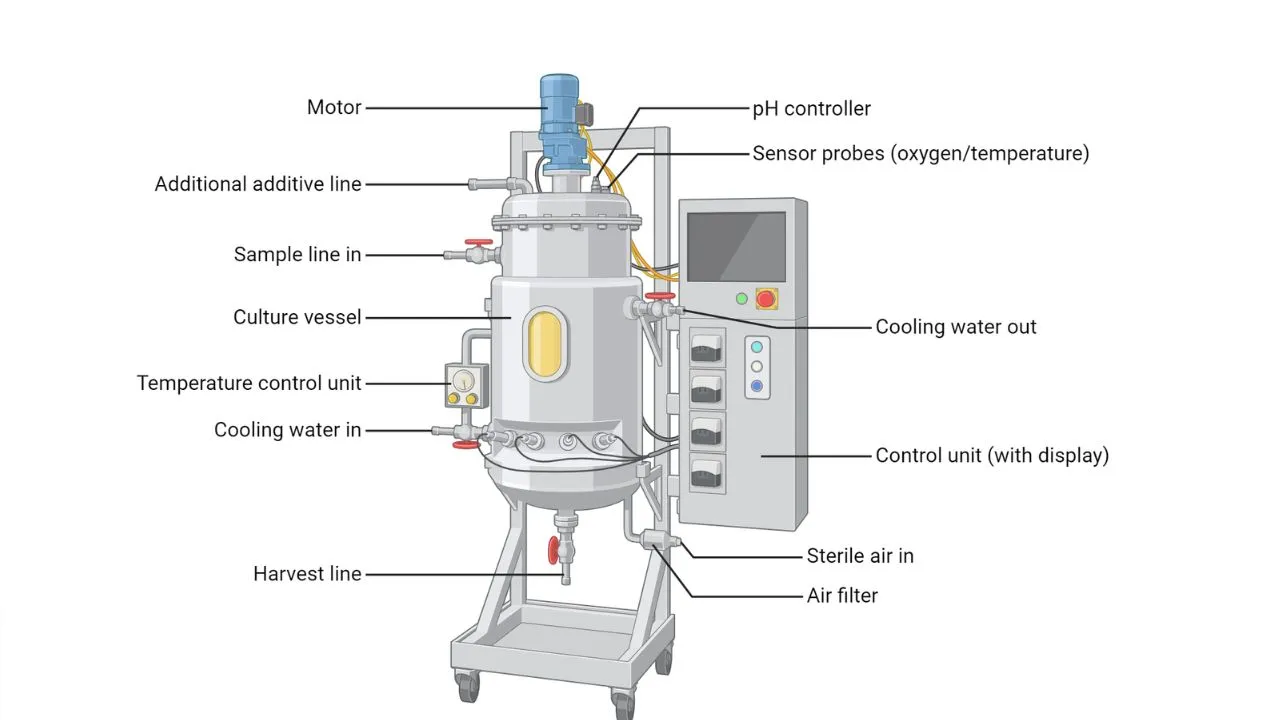

Bioreactor Parts:

A typical bioreactor consists of several key components, including:

- Vessel: The main chamber where the biological reaction occurs.

- Agitator System: Stirrers or blade for proper mixing.

- Sparger: For gas distribution and aeration.

- Baffles: Prevent vortex formation and improve mixing efficiency.

- Sampling Ports: Allow periodic sampling without contamination.

- Sensors and Controllers: Monitor and control parameters like temperature, pH, and dissolved oxygen.

- Cooling/Heating Jackets: Maintain the required temperature range.

At Fermenter Technologies, we offer bioreactors with high-quality stainless-steel construction, advanced automation, and safety features for both laboratory and industrial use.

Bioreactor Types:

Bioreactors come in various types based on the process and application. The major ones include:

- Stirred Tank Bioreactor (STR): The most common type, ideal for large-scale fermentation.

- Airlift Bioreactor: Uses air for mixing, reducing mechanical stress on cells.

- Packed Bed Bioreactor: Suitable for immobilized cell systems and continuous processes.

- Fluidized Bed Bioreactor: Improves mass transfer for high-density cultures.

- Photobioreactor: Used for algae and photosynthetic microorganisms.

Also Read: Scale Up of Fermentation Process

How Does a Bioreactor Work?

Step-by-Step Working

- Preparation: The vessel is sterilized, and nutrient media are added.

- Inoculation: The desired microorganism or cell line is introduced into the sterile environment.

- Controlled Growth: Temperature, pH, oxygen, and agitation are maintained using sensors and controllers.

- Product Formation: Cells grow and convert raw materials into desired products such as enzymes, vaccines, or biofuels.

- Harvesting: After completion, the biomass or product is separated, purified, and processed further.

Bioreactors Uses:

Bioreactors are indispensable across industries:

- Pharmaceuticals: Production of vaccines, monoclonal antibodies, and therapeutic proteins.

- Food & Beverages: Used in brewing, dairy fermentation, and enzyme production.

- Agriculture: Manufacturing biofertilizers and biopesticides.

- Energy: Biofuel and biogas production.

- Environmental: Wastewater treatment using microbial activity.

With sustainability becoming a global priority, bioreactors are crucial in developing greener solutions for industrial processes.

Bioreactor Diagram

A simple diagram of a bioreactor would typically show:

- Vessel (with jacket)

- Agitator with motor

- Sparger at the bottom for air supply

- Baffles along the walls

- Sampling and feed ports

- Sensors for monitoring pH, temperature, and oxygen

This setup illustrates how all parts work together to create an ideal environment for biological growth.

Why Choose Fermenter Technologies?

At Fermenter Technologies, we understand the challenges industries face in the scale up of the bioreactor process. We offer build-made Laboratory bioreactor solutions that are reliable, efficient, and easy to operate. Our systems are designed with state-of-the-art control panels, ensuring you achieve maximum productivity while maintaining quality and compliance. Whether you are a research lab, a pharmaceutical manufacturer, or a biofuel company, we have the right Bioreactor for you.